A flue gas analyser is one of the most essential tools for a heating engineer. But why should you look into smart flue gas analysers from CORGI Direct ?

There are numerous benefits to going smart, but here are our top 5:

With smart flue gas analysers, like the testo 300, smart probes can be easily connected wirelessly. This allows you to complete your job much faster while measuring multiple parameters at the same time.

The technology in the testo 300 smart flue gas analysers screen means that the analyser’s smart touch display reacts immediately and without delay. This results in faster and more efficient measurements of flue gas levels.

Easy navigation and intuitive menus. There is no need for complicated user display with a smart flue gas analyser, you can customise the ideal measurement parameters in the settings and then display just the information you need.

With a smart flue gas analyser, measurements can be saved and recorded to make documentation easy. These can then be sent straight to the customer wirelessly or archived as part of a commissioning process.

Testo flue gas analysers offer a robust housing and components, keeping it safe from day-to-day wear and tear.

As well as the smart testo 300, testo have a range of flue gas analysers to suit your needs! For more information, visit

https://www.corgi-direct.com/testo-flue-gas-analysers-18088-0000

___________________________________________________________

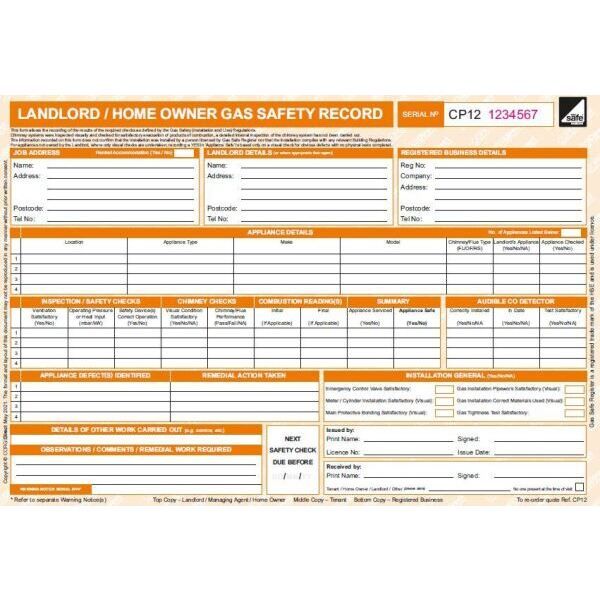

The CP12 Landlord / Homeowner Gas Safety Record has not only been modernised but takes account of the recent changes to Landlords requirements in the Gas Safety (Installation & Use) Regulations (GSIUR) that came into effect in April 2018. The CP12 also allows for additional recording of information and readability by the user and Landlord / Homeowner.

The new CP6 pad includes guidance on the cover (rather than rear of the form) to allow gas operatives to read the guidance while filling in the form that wasn’t possible on previous versions. Clearer layout that also allows for Client / Landlords details to be added (if required). Additional boxes included to allow a brief description of work carried out and the results of any installation visual inspections / tightness tests (if undertaken). Additional checks can be recorded such a flue integrity. Remedial work required, it is more clearly defined to the customer.

The multi-purpose pad to record the details of gas work undertaken. Can be used instead of the Gas Safety Inspection Pad (CP4) and the Service/Maintenance Checklist (CP6).

The CP14 Warning Notice was updated to reflect the recommendations contained within the Gas Industry Unsafe Situations Procedure Seventh Edition (GIUSP) and its subsequent replacement IGEM/G/11 (see also CORGI Direct Publication USP 1). It has been enhanced further at its last reprint, following your feedback, to highlight the ‘DANGER DO NOT USE’ message to your customers. The Warning Notice will ensure your customers fully understand that an installation/appliance is not safe. The essential form is to be used in accordance with the requirements of the current Gas Industry Unsafe Situations Procedure (Code: USP 1). Designed to record Immediately Dangerous (ID) and At Risk (AR) situations, this form provides detailed ‘how to complete’ notes to ensure accuracy and compliance making sure that all responsible parties are aware of the dangerous appliance/installation. ‘DANGER DO NOT USE’ Labels are also available to affix to the appliance/installation (Codes: WL 1 ).

Originally conceived and produced in-house, this important gas safety form allows the accurate documentation of catering installations – both the kitchen environment with its ancillary controls and the gas appliances themselves. This form has recently been reviewed and updated by our technical team, drawing on gas engineer's feedback and recent industry changes detailed in Gas Safe Register's Technical Bulletin – TB 140 'Guidance on ventilation and extraction requirements for commercial catering installations' – which was developed in conjunction with the Institution of Gas Engineers and Managers (IGEM). The publication of TB 140 replaces the established information contained within the HSE's Catering Information Sheet 23 (rev 1) Gas safety in catering and hospitality', which has been withdrawn pending an update. CORGIdirect's revised CP42 still draws upon the requirements of British Standard (BS) 6173 'Specifications for installation and maintenance of gas-fired catering appliances for use in all types of catering establishments (2nd and 3rd family gases)' but also reflects the latest technical requirements of TB 140. Continuing with the original forms format, this newly revised form is in two parts: Part 1 deals with the catering environment (gas installation and isolation, electrical, interlocks, exhaust and ventilation systems, etc.), but following customer feedback has seen the removal of the 'Risk Assessment' element that was a source of debate and confusion. The second Part deals with the appliance themselves.

You can see all the professional pads here - https://www.corgi-direct.com/corgi-forms-and-pads-17967-0000